Sports Lighting Photometric Plans

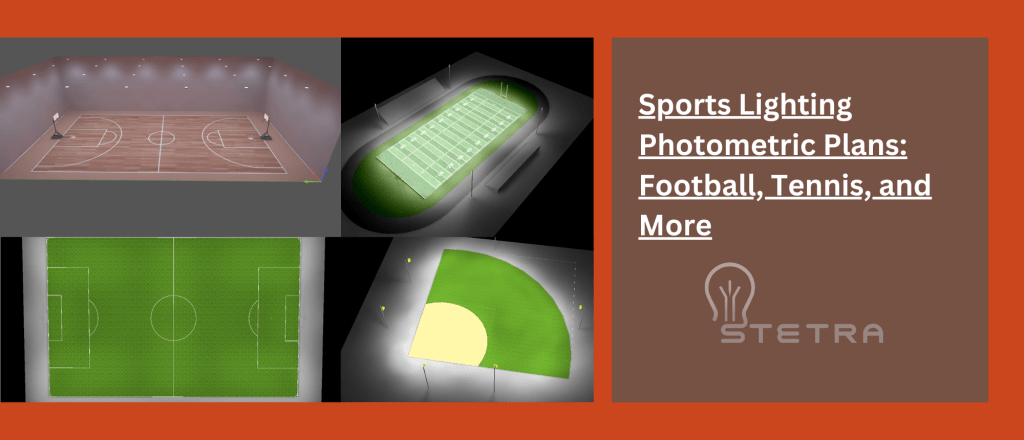

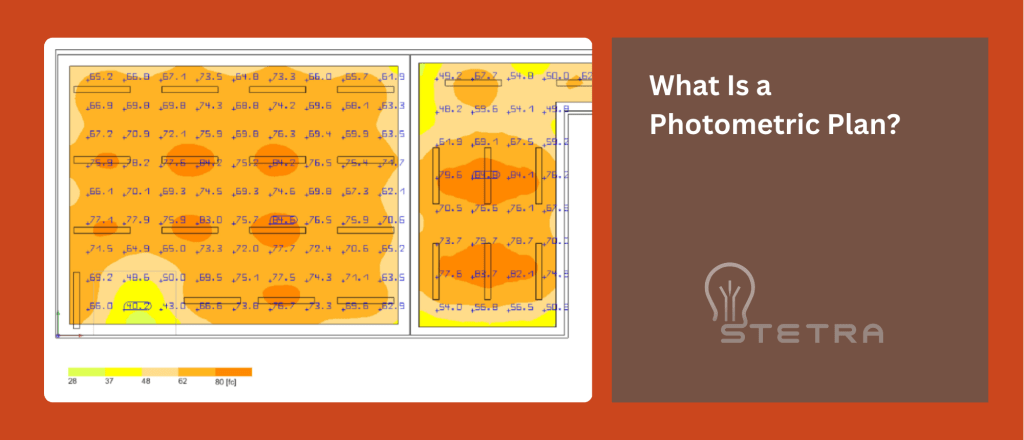

Sports lighting is performance lighting. It must support play, safety, and visibility across the full surface. A photometric plan is how you verify that performance before installation. It predicts foot-candle levels, uniformity, and where the weak areas will be. This is useful for owners, architects, engineers, and contractors. It reduces fixture guesswork, helps with permitting, and prevents expensive changes after poles and wiring are installed. In this guide, you will learn what a sports lighting photometric plan includes, how IES Classes (I, II, III) affect targets, and what to check for common sports facilities. What a Sports Lighting Photometric Plan Includes A sports lighting photometric plan is a performance document. It combines a layout drawing with calculated light levels so you can confirm brightness and consistency before purchase and installation. Most plans include a foot-candle grid, pole locations, fixture quantities, mounting heights, and optics. Many also include summary metrics such as average, minimum, maximum, AVG/MIN, and MAX/MIN. These metrics help you judge uniformity and spot problem areas early. Do not judge a plan by average fc alone. A good average can hide dark pockets. Always check the minimum values and the uniformity ratios. These are the numbers that affect play quality and user complaints. How Sports Lighting Photometric Plans Work in Practice Sports lighting performance comes from geometry and optics. Pole height, setback, fixture aiming, and beam distribution control both coverage and glare. A photometric plan lets you test these variables and see the outcome before procurement. Two projects can use the same wattage and still perform very differently. The difference is usually in optics (symmetric vs asymmetric), aiming angles, and how well the layout matches the playing surface shape. What to Verify Before You Approve the Plan Use the plan to verify outcomes, not fixture count. Look for balanced distribution, strong minimum values and good uniformity. Then review aiming and spill control. Sports Lighting Types and IES Classes (I, II, III) Sports lighting requirements vary by field size, player speed, viewing distance, and level of competition. The IES Class system is commonly used to define performance expectations and typical foot-candle targets. The IES Class system is commonly used to define performance expectations for sports lighting. Class I applies to high-level competition and broadcast environments, while Class II supports organized leagues and competitive play. Class III is most often used for recreational and community facilities. The ranges below reflect typical planning targets and should always be verified with a photometric plan. Football and Soccer Field Lighting Football and soccer fields are large areas that rely on higher mounting heights and long-throw asymmetric optics. Uniform horizontal illuminance and consistent coverage across corners and sidelines are critical for safe play. Typical planning targets: IES Class III: ~30–50 fc IES Class II: ~50–75 fc IES Class I: 75+ fc Uniformity ratios and spill control are as important as the average level, especially for community fields near residential areas. Baseball and Softball Field Lighting Baseball and softball fields require different lighting priorities for the infield and outfield. Vertical illuminance is critical for tracking the ball, especially for batters and fielders looking upward. Typical planning targets: Infield (Class III): ~40–60 fc Outfield (Class III): ~20–30 fc Class II / Class I: higher targets with added vertical illuminance requirements Careful aiming and glare control are essential due to the directional nature of play and varied sight lines. Tennis Court Lighting Tennis is highly glare-sensitive. Players frequently look upward to track the ball, making optic control and aiming critical. Uniformity behind the baselines is often more important than peak light levels. Typical planning targets: IES Class III: ~30–50 fc IES Class II: ~50–75 fc IES Class I: 75+ fc Good tennis lighting minimizes high-angle glare while maintaining even coverage across the full court width. Basketball Courts (Indoor and Outdoor) Indoor basketball lighting focuses on glare control, vertical illuminance, and smooth uniformity from ceiling-mounted fixtures. Outdoor courts must also address spill light and neighborhood impact. Typical planning targets: Indoor Class III: ~30–50 fc Outdoor Class III: ~30–60 fc Class II / Class I: higher levels depending on competition and viewing requirements Optic selection and mounting height play a larger role than raw wattage in achieving good results. Pickleball Court Lighting Pickleball courts are compact but highly sensitive to glare. Lower mounting heights and close player proximity make fixture aiming and shielding critical. Typical planning targets: IES Class III: ~30–50 fc IES Class II: ~50–70 fc Consistent edge lighting and glare reduction often matter more than increasing overall brightness. Ice Hockey Arenas and Natatoriums Ice rinks and pool environments introduce reflective surfaces that increase glare and sparkle. Uniformity and careful fixture placement help control reflections and improve visibility. Typical planning targets: IES Class III: ~40–60 fc IES Class II / Class I: higher targets depending on viewing and broadcast needs False-color views and 3D renderings are especially valuable for evaluating these environments before installation. Common Mistakes and How to Avoid Them Most sports lighting failures are predictable. They happen when the design is based on wattage, fixture count, or a single average number. A proper photometric plan makes the weak spots visible before installation. What a Permit-Ready Sports Lighting Report Should Deliver A strong sports lighting report is easy to approve and easy to build. It clearly states the IES Class target, shows foot-candle grids, includes uniformity metrics, and provides visuals that non-technical stakeholders can understand. It also lists fixture types, mounting heights, and assumptions such as light loss factors. This is also where the plan becomes a contractor tool. Clear pole positions, aiming intent, and fixture schedules reduce field questions and keep installation aligned with the design. When you want confidence before purchase, a professional photometric plan is the fastest path. It aligns the owner, designer, and contractor on measurable performance. Get a Professional Photometric Plan We create accurate photometric plans ready for permitting, contractor installation, and real-world performance. Key Takeaways If you want a sports lighting layout that performs the first time, use a verified photometric

Sports Lighting Photometric Plans Read More »