A parking lot photometric plan is more than a colored grid on a drawing. It is the document that proves your exterior lighting meets safety, code, and owner expectations.

This guide explains how to read and design a parking lot lighting plan, what uniformity ratios mean, and which requirements matter most for architects, engineers, and contractors.

Why a Parking Lot Photometric Plan Matters

Most lighting issues in parking lots start with an incomplete or low-quality design. Once poles are installed, fixing dark spots, glare, or neighbour complaints becomes expensive. A proper photometric plan helps you catch problems on screen before they appear on site.

See Lighting Performance Before Construction

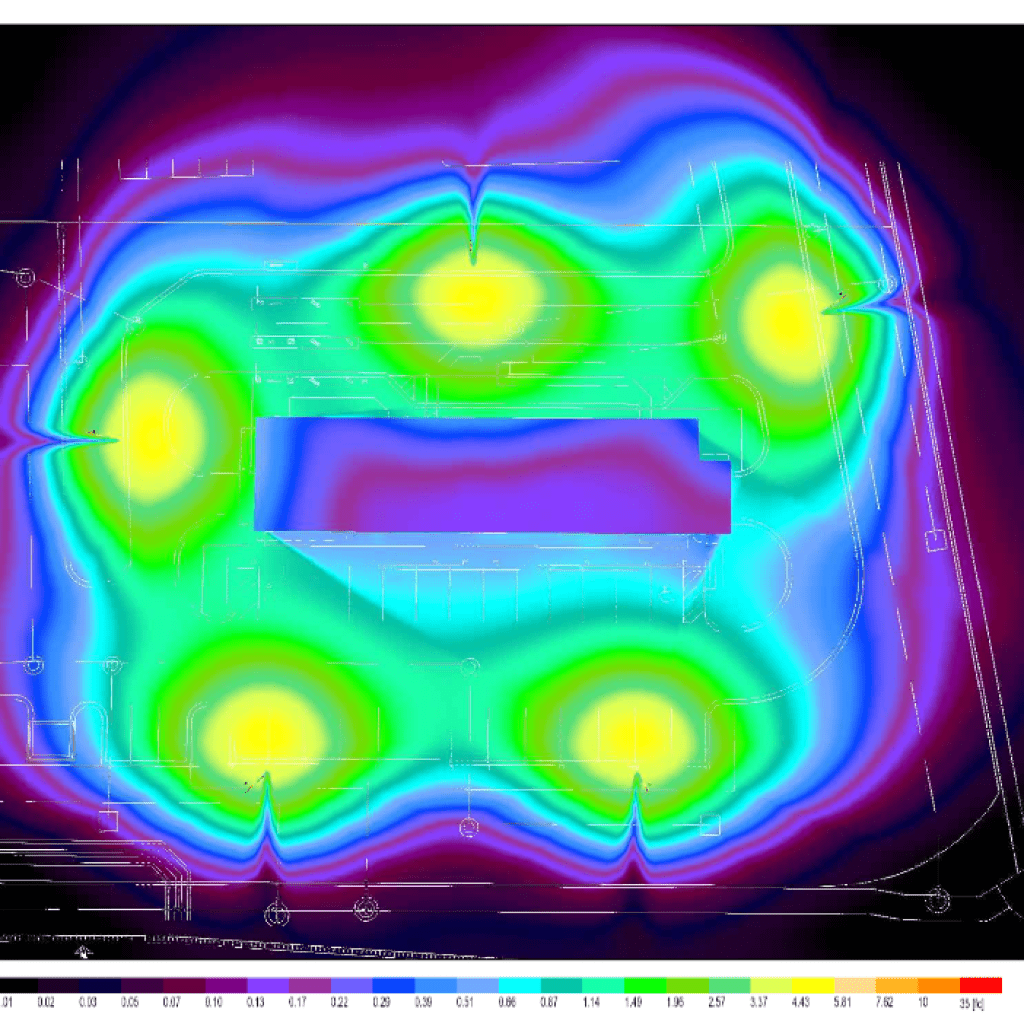

A photometric study lets you check light levels, uniformity, and spill light before any pole is ordered. Instead of guessing, you can show the owner and the authority having jurisdiction (AHJ) exactly how the lighting will perform at night.

- Confirm minimum and average foot-candle levels for drive lanes and parking stalls.

- Review uniformity ratios so there are no harsh transitions between bright and dark zones.

- Check light trespass and glare at property lines, neighboring buildings, and roadways.

For owners, a clean photometric plan builds confidence that their parking lot will feel safe and easy to navigate at night. For designers, it is the technical proof that fixture selection, pole heights, and spacing are correct.

Key Metrics in a Parking Lot Photometric Plan

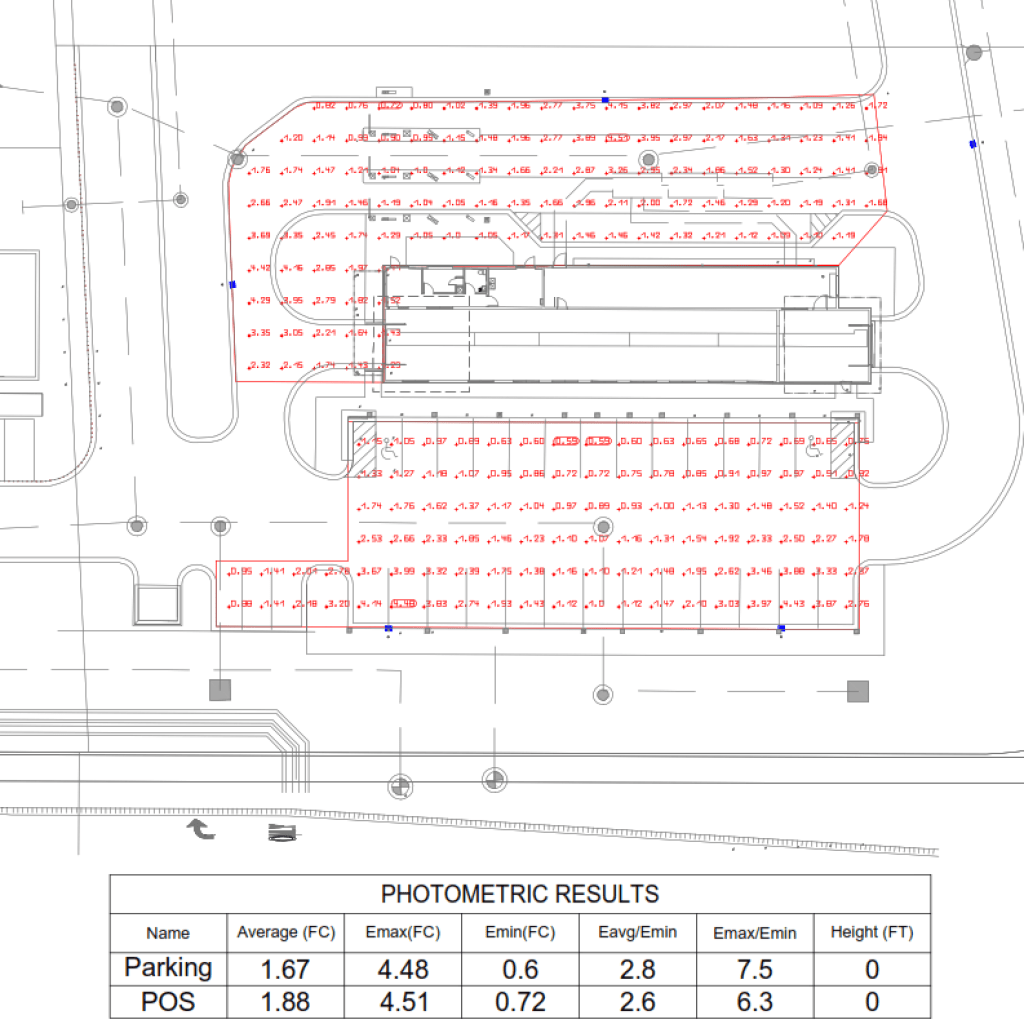

Every parking lot design should clearly show light levels and ratios. These metrics tell you if the layout is both comfortable and code-compliant. Most U.S. projects use foot-candles (fc) at grade to describe horizontal illuminance.

- Average foot-candles (Avg FC) – the overall brightness level across the calculation area.

- Minimum foot-candles (Min FC) – the darkest points on the grid, critical for safety and visibility.

- Max FC – the brightest points, which can cause discomfort or glare if too high.

- Uniformity ratios – typically Avg:Min and Max:Min, used by many standards and AHJs.

- Calculation areas – separate grids for parking bays, drive aisles, entrances, and sometimes walkways.

Many designers reference the Illuminating Engineering Society recommendations when setting targets. You can explore current guidance at IES.org and then adapt it to your local codes and project needs.

Uniformity Ratios, Light Levels, and Glare Control

Uniformity ratios describe how even the lighting is across the lot. A good parking lot photometric plan keeps Avg:Min and Max:Min within the ranges recommended by IES and local standards, while still meeting target foot-candle levels.

- Avg:Min ratio – many exterior parking lots aim for 3:1–4:1 to avoid dark patches.

- Max:Min ratio – keeping this under 10:1 helps prevent high contrast and discomfort.

- Glare and BUG ratings – selecting optics with proper backlight, uplight, and glare control.

| Requirement | U.S. Standard / Typical Value | Description |

|---|---|---|

| Average Light Level (Avg FC) | 0.8 – 2.0 fc | Typical IES RP-8 recommendation for general parking areas. |

| Minimum Light Level (Min FC) | 0.2 fc | Lowest acceptable value for safe visibility in most U.S. parking lots. |

| Drive Lanes – Avg FC | 1.0 – 2.5 fc | Higher illumination helps drivers identify pedestrians and vehicles. |

| Pedestrian Paths – Min FC | 0.5 fc | Areas where people walk require stronger visibility. |

| Avg:Min Uniformity Ratio | 3:1 – 4:1 | Standard for comfortable, even lighting without dark patches. |

| Max:Min Uniformity Ratio | ≤ 10:1 | Prevents harsh contrast between bright and dark zones. |

| Glare Control | BUG Rating per TM-15 | Most municipalities require controlled uplight and backlight near property lines. |

| Property Line Limit | 0.1 – 0.5 fc (AHJ-specific) | Light trespass limits along neighboring lots or residential areas. |

| Pole Height | 20 – 30 ft typical | Selected to balance uniformity, distribution, and glare. |

| Calculation Grid | 10 ft spacing | Standard grid resolution for parking lot photometric plans. |

When Stetra Lighting prepares a parking lot photometric plan, we test several layouts and distribution types. The goal is to meet project standards with as few poles as practical while keeping the site comfortable, legible, and neighbor-friendly.

Example: Fixing a Poor Parking Lot Layout

To see how this process changes a project, it helps to look at a real scenario. Many projects come to us after the first layout fails to meet either the owner’s expectations or the city requirements.

- Project / context: Medium-size retail parking lot with 25 ft poles and area lights on a 1:1 spacing pattern, designed only from a catalog cut sheet.

- Challenge: The initial study showed dark corners, high contrast near the main entrance, and Max:Min ratios exceeding 20:1 in some drive lanes.

- Result: After revising the parking lot photometric plan, adjusting pole locations, and changing optics, we achieved target average light levels with an Avg:Min ratio under 4:1 and Max:Min below 10:1, while using the same fixture family.

- Extra benefit: The updated design reduced energy use by removing two poles and optimizing light distribution instead of simply adding more wattage.

This kind of optimization is only possible when the plan is treated as a design tool, not just a permit drawing. It lets the whole team see the impact of every pole shift, tilt angle, and lumen package change.

Get a Professional Photometric Plan

We create accurate photometric plans ready for permitting, contractor installation, and real-world performance.

Key Takeaways for Parking Lot Photometric Plans

A strong parking lot design starts with a clear, well-documented photometric plan. When you understand light levels, uniformity ratios, and how fixtures actually distribute light on the ground, you avoid surprises after installation.

Before you order fixtures or pour foundations, make sure your parking lot photometric plan has the right targets, ratios, and calculations in place. If you need support, Stetra Lighting can prepare a professional, permit-ready design tailored to your site, fixtures, and local requirements.